EVERLAST METALS: DL-100

Metal Roofing Panel Profile

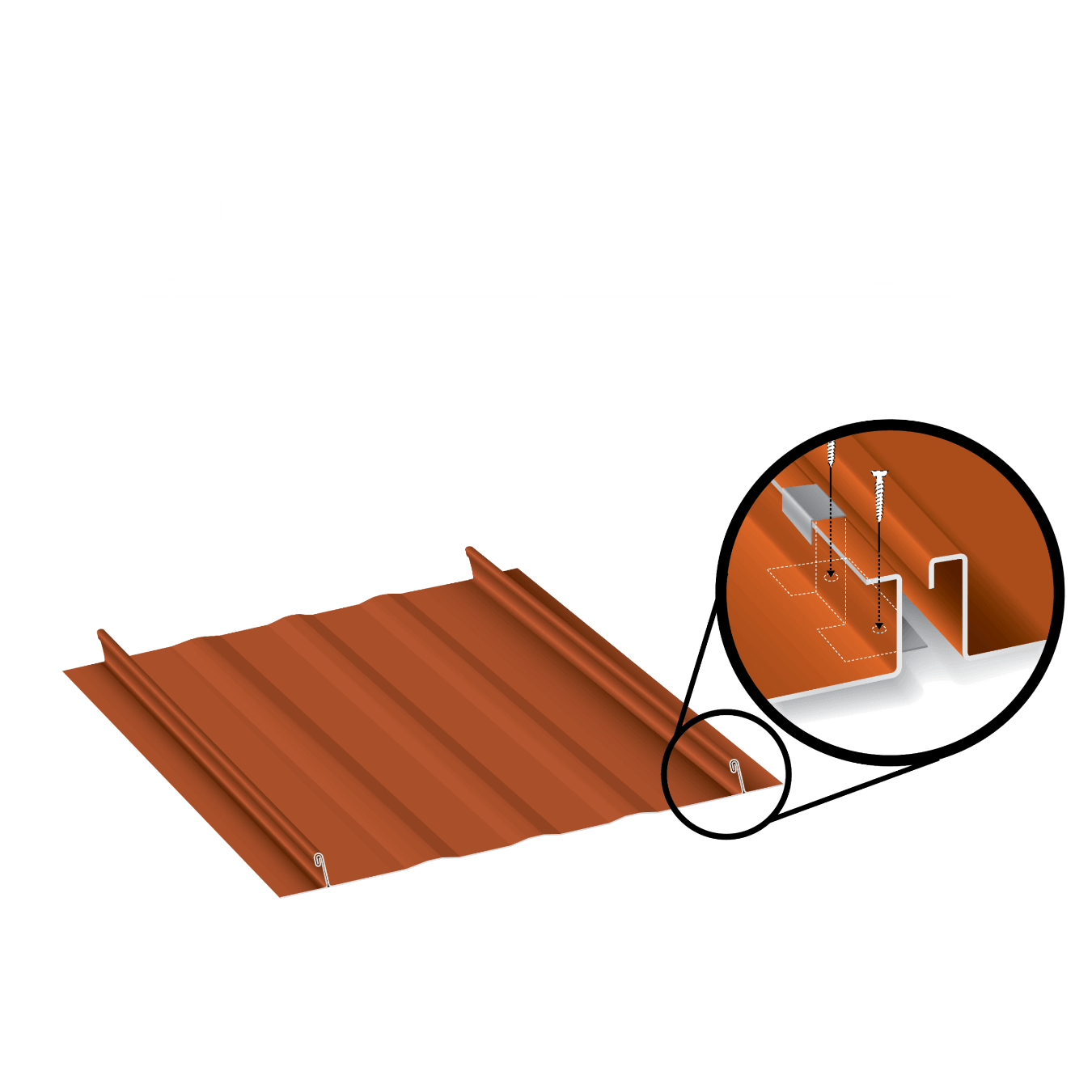

Everlast Metals DL-100 Double-Lock Standing Seam roofing panel utilizes the proven seaming process of Mechanical Locking in conjunction with the floating action of a concealed clip assembly.

This design allows for expansion & contraction caused by natural elements, providing a virtually leak proof roof with exceptional wind uplift ratings.

The panel is available in a wide variety of materials and finishes. Substrates include G-90 Galvanized Steel, Galvalume® steel, and Aluminum. All painted products are Fluropon® coated.

An optional thermally applied pre-assembly in-seam sealant is available. The minimum slope requirement is 3:12.